If you are looking for Let's stream fallout 4 – YouTube you’ve visit to the right page. We have 35 Images about Let's stream fallout 4 – YouTube like How To Download Plugins For Better Discord On Github, Fallout 4 Load Order Survival Guide Update and also Fallout 76 Discord Servers [Active 2023] – DSL. Here you go:

Table of Contents

Let's Stream Fallout 4 – YouTube

www.youtube.com

At Fallout 4 Nexus – Mods And Community

www.nexusmods.com

Fallout 4: Frost, Starbound, Discord! |Ep.4| Talking With The Soul

www.youtube.com

Fallout 4 – Early Morning Building, Giveaway In Discord – YouTube

www.youtube.com

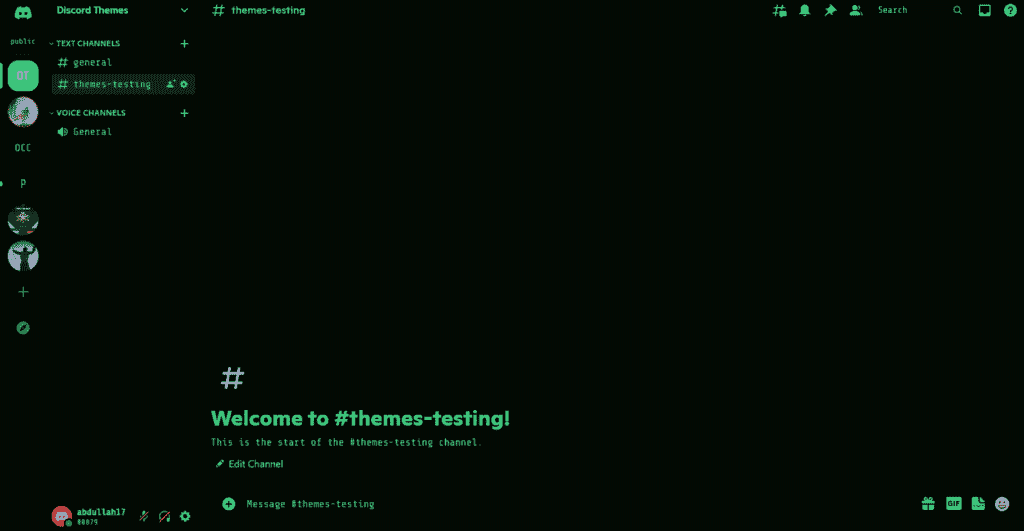

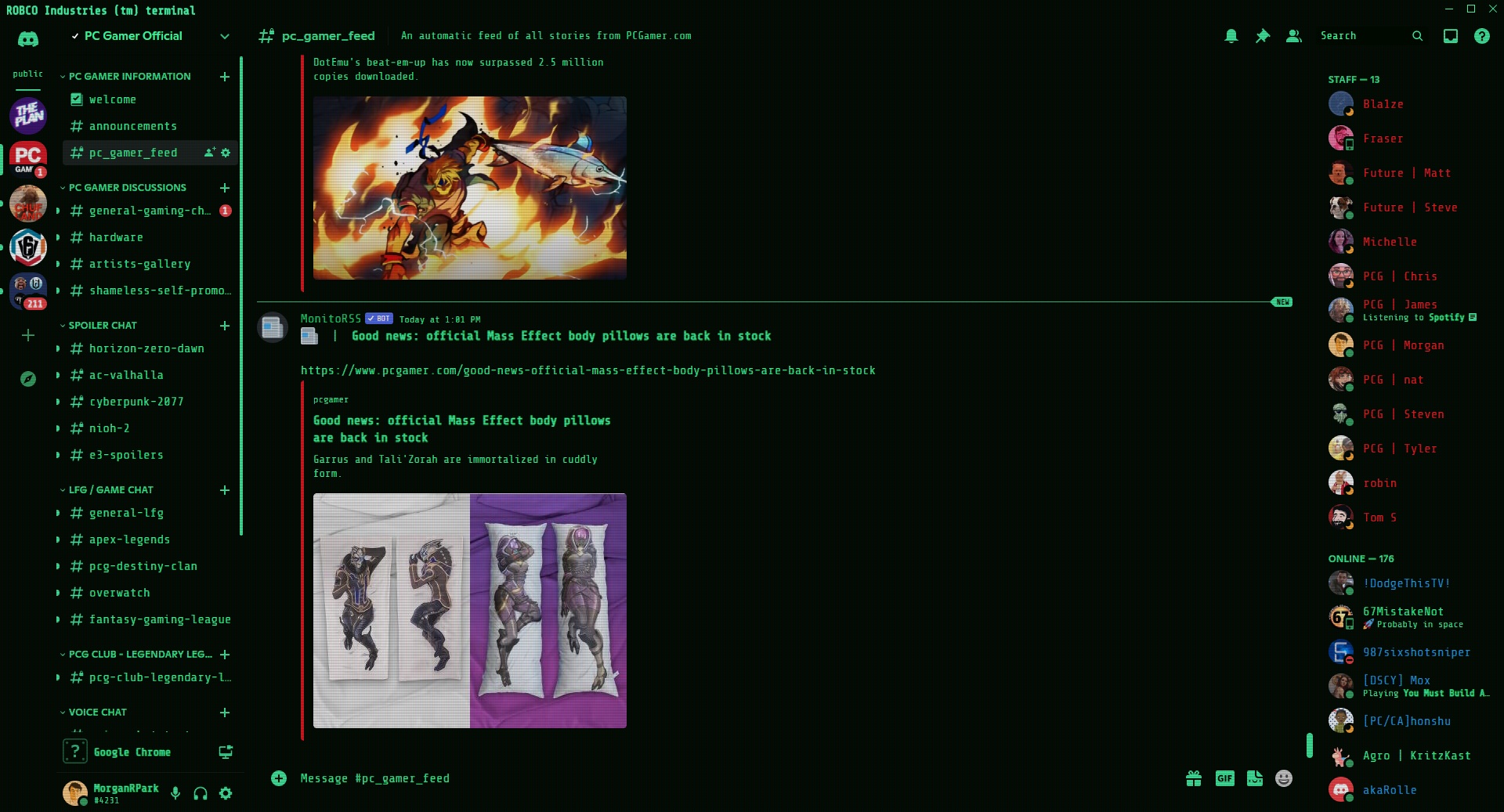

10 BEST Discord Themes: Ranked (2022) – GadgetGang

gadgetgang.com

Fallout 4 Cordless VII Discord Challenge Red Rocket – YouTube

www.youtube.com

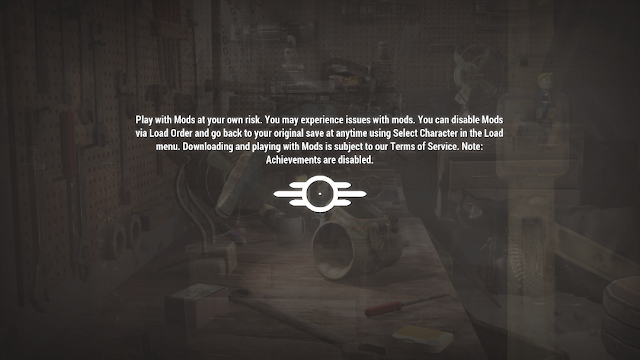

MUST HAVE Fallout 4 Stability Mods + How To Bypass The 255 Plugin Limit

10s.vn

Fallout 4 Load Order Survival Guide Update

oddlittleturtle.com

[Stream] Fallout 4: Part 1 – YouTube

![[Stream] Fallout 4: Part 1 - YouTube](https://i.ytimg.com/vi/l-c5FiYEahg/maxresdefault.jpg)

www.youtube.com

Stream – Fallout 4 Survival – 26 – The Railroad! – YouTube

www.youtube.com

railroad fallout

Fallout 4 Overlay Does Not Work : Solved Discord Overlay Not Working

rusdinaomi.blogspot.com

fallout

STREAM – FALLOUT 4 – PARTE 9 – YouTube

www.youtube.com

Fallout 4 Discord Challenge Jan 2018 – YouTube

www.youtube.com

fallout

Fallout 4 Live Stream – YouTube

www.youtube.com

Stream – Fallout 4 – Random Mods Goofing Around – YouTube

www.youtube.com

Fallout 4 – Second Stream – YouTube

www.youtube.com

Turning Fallout 4 Into Escape From Tarkov // !TarkovTweaks // !Discord

lienket.vn

Fallout – Discord Overworld Snippet By Matt Anderson For Canopy On Dribbble

dribbble.com

fallout discord overworld snippet dioramas emojis safari kindpng

Fallout 76 Discord | How To Join

deasilex.com

FALLOUT4 Live Stream FALLOUT Episode 17 Walk Through Gameplay – YouTube

www.youtube.com

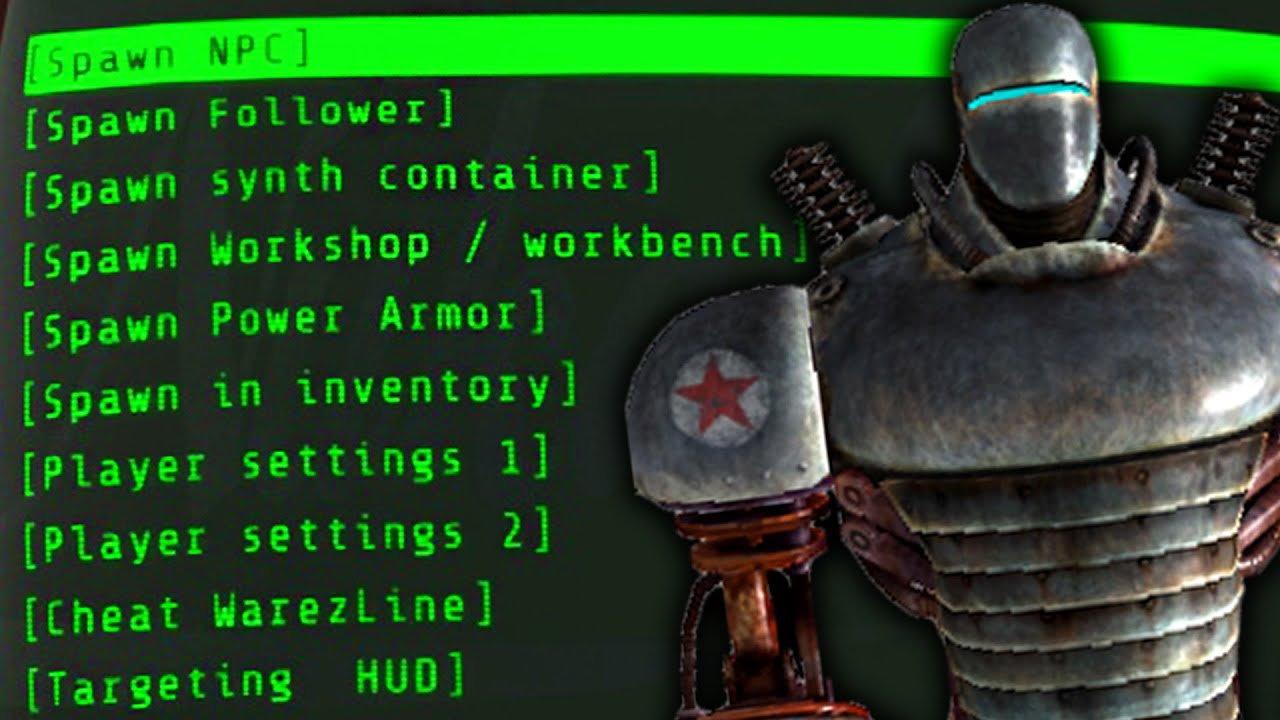

DIscord At Fallout 4 Nexus – Mods And Community

www.nexusmods.com

fallout

STREAM – FALLOUT 4 – PARTE 10 – YouTube

www.youtube.com

STREAM – FALLOUT 4 – PARTE 27 – YouTube

www.youtube.com

Fallout 4 ( Ep2 Live Stream ) – YouTube

www.youtube.com

Streaming Fallout 4 – YouTube

www.youtube.com

Fallout 4 – Live Stream [Part 1] – YouTube

![Fallout 4 - Live Stream [Part 1] - YouTube](https://i.ytimg.com/vi/ckLaQl49DDc/maxresdefault.jpg)

www.youtube.com

Top 7 Discord Themes

candid.technology

Fallout The Frontier Discord : R/FalloutTheFrontier

www.reddit.com

How To Download Plugins For Better Discord On Github

dewittwarlicke0194477.blogspot.com

[TOTAL CONVERSION MOD] -^- GROUND SPACE TERRA -^- Fallout 4 – Discord

![[TOTAL CONVERSION MOD] -^- GROUND SPACE TERRA -^- Fallout 4 - discord](https://static.loverslab.com/uploads/monthly_2019_07/202.jpg.dcb8ebdf500095ac67fdb513a3f8519f.jpg)

www.loverslab.com

loverslab

FALLOUT RP | 1.13.2 | Roleplay | Custom Coded | IN DEVELOPMENT

www.planetminecraft.com

Fallout 4 Live Stream Part 12 – YouTube

www.youtube.com

Fallout 4 – Settlement Upgrades, Giveaway In Discord – YouTube

www.youtube.com

discord fallout

Fallout 76 Discord Servers [Active 2023] – DSL

![Fallout 76 Discord Servers [Active 2023] - DSL](https://discordserverlists.com/wp-content/uploads/2021/09/wallpapersden.com_fallout-76-2020_1920x1080-1-758x426.jpg)

discordserverlists.com

14 Best BetterDiscord Themes To Elevate Your Discord Experience

tech4fresher.com

Fallout rp. Discord at fallout 4 nexus. At fallout 4 nexus

ataylormadelife.com ataylormadelife.com adalah website berita yang memberikan informasi seputar teknologii dan games

ataylormadelife.com ataylormadelife.com adalah website berita yang memberikan informasi seputar teknologii dan games